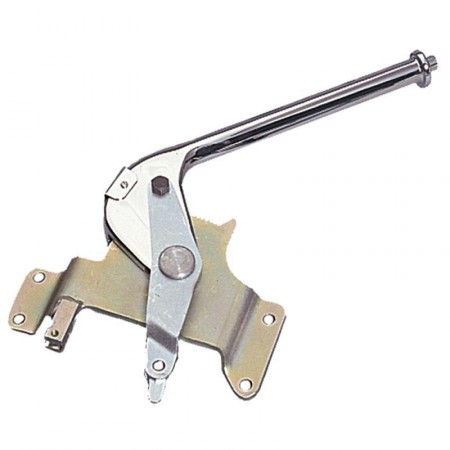

The missing handbrake parts for the warning light switch were ordered from SNG Barratt – the bracket, switch and ‘S’ shaped spring. It looked fairly obvious how it should all go together but what puzzled me was the parts list indicated only two nuts are required to secure both the switch and spring to the bracket.

The switch is actuated by a finger-like protrusion at the base of the handbrake arm, which should press against the spring as the handbrake is nearing the fully released position. This causes the spring to depress the switch’s plunger, breaking the circuit and so switching the warning light off.

The only way I could get the switch’s plunger anywhere near to the ‘finger’ protrusion was to mount the switch to the bracket and then use two locking nuts to position the spring at the end of the switch – as shown in the photo.

I’ll be swapping to half nuts to secure the spring but pressing the spring just about operates the switch. However the problem is the ‘finger’ protrusion of the handbrake only just brushes the spring and doesn’t push it against the switch.

I posted the photo on the E-Type forum and within no time at all the moderator, Angus, had responded, directing me to an image of the correct set-up on a S2 car currently going through his workshop, Moss Jagaur.

I went backwards and forwards between the two set-ups but still couldn’t see how mine was so far out. After all, the geometry is fixed. Eventually I noticed the length of my cable fork was much longer and then it dawned on me what was wrong.

My handbrake had been hacked about at some time in the past. The bracket attachment has been cut off and welded further back.

My handbrake had been hacked about at some time in the past. The bracket attachment has been cut off and welded further back.

There had been some obvious welding around the attachment point but I had assumed this was just a repair to strengthen it and, as it has come off the car, was correct. It now explains why they hadn’t refitted all the switch parts!

The annoying thing is all the parts have been re-plated and the ratchet teeth are all in good condition. I think I’m going to keep it ‘as is’ and adapt the bracket, although it’ll bug me now!

Further responses to my forum post pointed out that the handbrake cable is an incorrect reproduction item, which would explain why the clevis fork is longer but more importantly that they cables are too long to get the handbrake to work correctly.

The repro cables have been on sale for many years, and still are!, and it points to a previous owner having gone the wrong way trying to find a solution to the problem. The repro cable problem had been picked up by Jaguar Enthusiast Club, who now offer the correct cable so one is now on order.

It’s cases like this where the E-Type forum is invaluable. There are members with a wealth of knowledge of these cars who are happy to spend time offering others advice and solutions to their problems.

Sorry, the comment form is closed at this time.