I’d been lucky to have an opportunity to drive an unmolested E-Type while on my recent travels (Sydney in an E-Type) and wanted to return the favour when the Christopher was next back in the UK. Not least because he would be able to give valuable feedback, good or bad, on how the two cars compare.

| Crossing the Sydney bridge in an E | Christopher’s original S2 FHC |

|---|---|

|

|

I had experienced slight gear selection issues with mine when changing from 2nd to 3rd and from 3rd back down to 2nd – something I might cover in a future post. Although these were more due to being used to modern gearboxes and resolved by adopting a more sympathetic technique changing gears.

I had decided to keep reasonably close to the original spec. The most noticeable differences are the EDIS electronic ignition system and the Mangoletsi cable throttle linkage. The EDIS system hasn’t been properly mapped yet so the only real difference between our cars was the throttle linkage.

Christopher’s visit coincided with the car’s trip up to the trimmers to fit the hood. It had been up with Suffolk & Turley for a lot longer than expected and so the only opportunity for a drive was on the day he was returning to Australia.

This would have been fine had the MOT not expired while it was up at the trimmers. It had been there so long I hadn’t had an opportunity to organise a test since getting it back and now the speedo had seized. It might be possible to get away with a broken speedo on a modern car as the MOT tests are all static and the brakes tested on rollers.

However due to the limited slip differential, the E-Type had to be tested out on the road whilst travelling at 20mph. Braking efficiency is measured using a calibrated decelerometer. Therefore it would be glaringly obvious that the speedo wasn’t working. So it was a race against time to get the car road legal before he left. No pressure then!

To make matter worse, I’d noticed the ignition warning light wasn’t going out indicating the battery wasn’t charging. I had a matter of days to resolve both issues and get the car through the MOT. Things weren’t looking too promising, especially when I contacted Speedograph Richfield as the speedo hadn’t turned up as expected. I had specifically asked for a 24 hour delivery but they had forgotten, sending it out 2nd class and without the ability to track it. Aaaaaah …. and relax!

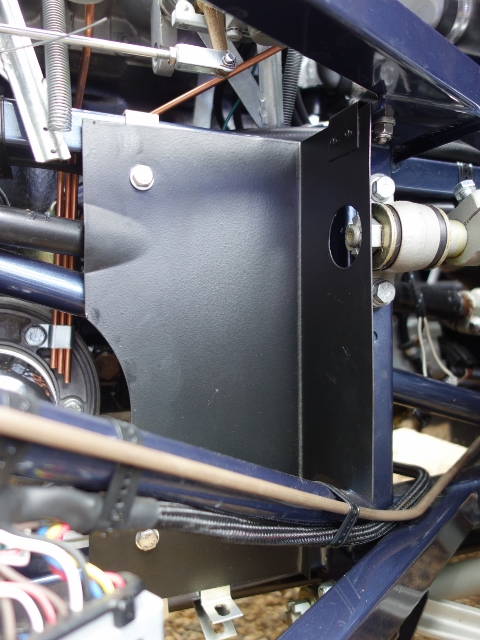

I was more concerned about the charging system since I had modified my alternator to a more modern design. This eliminates the 3AW and 6RA relays so the only two things that could be wrong were the 4TR voltage regulator or the alternator itself.

| Modified alternator doesn’t need 3AW and 6RA relays … less to go wrong! |

Three additional diodes (trio) have been added to self-energise the field coil |

|---|---|

|

A failed 4TR regulator is fairly easy to diagnose. The unit is simply removed and a jumper lead used to link its connector’s F and – terminals together. Essentially this just puts the full battery voltage across the field winding and removes the feedback loop.

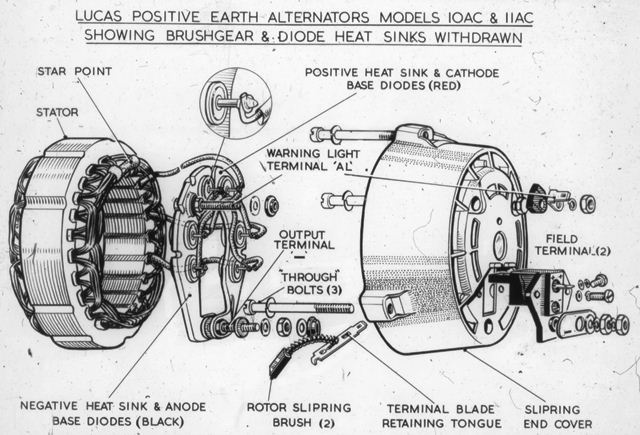

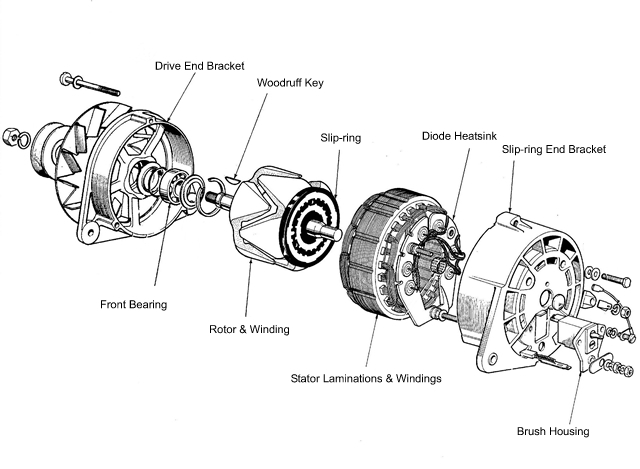

Alternator components

As the alternator starts spinning it’s output voltage increases. Without the feedback, the increased output increases the current in the field coil which, in turn, increases the alternator output voltage.

It would quickly reach a run away situation and burn out the alternator coil. Therefore, as soon as you’ve registered that the output voltage is increasing, you need to immediately switch off the engine.

I had pre-ordered another 4TR unit as a precaution but it wasn’t found to be faulty. It was the alternator. The modifications I’d made to the internal electrics and external wiring give it a ‘soft start’. The voltage across the field winding starts at approx. 1.5v rather than the full 12v battery voltage.

This is because the battery voltage is applied across the ignition warning light bulb (approx. 300 ohms) in series with the field winding (approx. 4 ohms). Hence the lions share of the voltage drop is across the bulb rather than the field winding.

The measured voltage without the engine running was 2.74v which seemed a little high. I incorrectly deduced this would result in an increased current flowing in the field coil, which wouldn’t be a bad thing. Once the engine was started, this voltage only rose to 6.36v rather than the expected 14.4v.

| The rotor field coil voltage was higher than the expected 1.5v |

With engine running, the field coil voltage should rise to 14.4v |

|---|---|

|

|

A reduced output typically points to failed diodes in the rectifying bridge. This became my main focus. The bridge needs to be removed from the 3-star stator windings in order to test the diodes. So the alternator had to be taken apart and it revealed some interesting problems.

The AL post’s insulating piece had disintegrated. I wasn’t able to source a new one and had to rebuild it as best I could, with araldite making up for the missing bits! Not ideal but it should do for now.

| Pulling the pulley wheel | AL post insulator had disintegrated | Temporary fix – rebuilt with araldite |

|---|---|---|

|

|

|

The original slip rings piece was found to be cracked so I had replaced it when the alternator was rebuilt. The replacement has raised sections between the rings but, as the brushes sit either side of them, I thought nothing of it.

These raised sections had been in contact with the brush holder and had worn a groove in the nylon housing. The slip rings looked clean enough but I gave them quick polish with wire wool.

| Difference between slip rings | Signs of rubbing on raised sections | Groove worn in brush housing |

|---|---|---|

|

|

|

My multimeter has a diode checking function so it was easy to check the diodes once the bridge had been removed. My suspicions were that one or more of the additional three diodes I’d added for the alternator modification had failed. They hadn’t and all the diodes were fine.

| Removing the rectifying bridge | Diodes can now be tested |

|---|---|

|

|

The other standard checks were made; the resistances of the rotor field and stator windings and the insulation between the rotor coil & rotor and the stator winding and stator laminations. All were fine … and I was stumped.

The alternator was rebuilt and put back on the car to test but there was no change. The ignition warning light stubbornly refusing to go out. I was getting fairly despondent. It was lunchtime, the alternator was in pieces on the bench yet again, there was no sign of the speedo, the car had no MOT and Christopher was due to turn up first thing the following morning!

For some reason I decided to measure the combined resistance of the rotor field winding and brushes. The rotor winding should be around 4 ohms. With the brushes included, I would have expected something in the order of 5 to 10 ohms (max). It varied between 30-40 ohms depending on the rotational positon of the rotor. This was way too high and would result in a significant reduction in the current in the rotor winding and therefore the output of the alternator.

| Slip rings required light sanding | Checking coil to rotor insulation |

|---|---|

|

|

As a last resort and even though the slip rings had initially been cleaned with wire wool, their surfaces were sanded down with a fine wet and dry sandpaper. The combined resistance dropped to only 7 ohms. The alternator was quickly rebuilt and tested. Eureka – it was working!

I’m fairly sure the cause was due to the slip rings impacting the nylon brush housing. The resulting friction had melted the nylon to form the groove and some of the molten nylon had formed a glaze on the slip rings. The sharp points of the multimeter’s leads would penetrate the glaze to give a false impression of the resistance seen by the brushes.

I was expecting an initial voltage across the field winding of 1.5v rather than the measured at 2.74v. The higher voltage was due to a high combined resistance of the field coil and brushes compared with the 300 ohm bulb.

Refitting the alternator

… for the 4th time!

In total I had removed the alternator, taken it apart, tested each component, rebuilt it and retested it four times to get it working!

It was such a relief to get to the bottom of the problem and things started to look up when the postman arrived clutching the speedo. The garage kindly rescheduled things and its second MOT was passed late in the afternoon.

The following morning Christopher and I headed off for a drive and dropped in on his parents. His father had also had an E-Type years ago so it seemed fitting to vacate my seat so he could also go for a spin.

The feedback on how the two cars compared was positive too. The driving experience was very similar which was pleasing as there’s always a fear a restoration could change things for the worse.

Chris takes his father for a spin

One item that got the thumbs up was the PD Gough exhaust which has a lovely throaty roar from 2,500 rpm.

Something I can thank the administrator of the E-Type forum for as his advice was to stick to the standard cast manifolds, avoid the big bore systems and fit 1.75″ tubes with straight through silencers and straight through resonators.