At some stage the previous owner had fitted an aftermarket 16″ Moto-lita steering wheel. Even though there was absolutely nothing wrong with it, I was toying with the idea of swapping for either a 15″ or possibly even a 14″ wheel, which a number of owners fit to increase the leg room. The steering would also be more direct with the smaller wheels with the obvious trade off being progressively heavier steering around town and parking.

Still, the unanswered question was, how much heavier would the steering become? Finally I decided to stick with my approach of keeping to the standard specification and only making changes once I’d driven it for a while. However, while I was dithering on what to do, I got distracted by an original rather ropey 16″ wheel on eBay. The wood had dried and split beyond repair so it needed to be re-rimmed … as though I didn’t have enough to be getting on with already!

| 16″ Moto-lita wheel |

Original wheel from eBay |

Splits in the wooden rim |

|

|

|

The splits in the rim ran almost for the full circumference which made its removal very straight forward. Fortunately there are a couple of people offering replacement mahogany rim kits. The new rims are ever so slightly thicker and so will have the benefit of being more rigid.

Unlike the very early E-Type steering wheels, the aluminium ring is entirely enclosed, in a groove cut into the bottom half of the wooden rim. The two halves are then bonded and a gloss varnish applied to the wood.

| Splits made removal a doddle |

Aluminium section freed |

Replacement rim kit |

|

|

|

The Series 2 steering wheels changed from the polished finished to avoid the reflective surface. I wasn’t convinced I’d be able to get a satisfactory brushed effect and so have decided to go for a polished finish.

The numerous scratches and light pitting in the aluminium section were too deep to be removed by polishing alone. So it was necessary to lightly sand it to remove the blemishes, prior to polishing. Initially 600-grit paper was used and then 800-grit until the scratches had disappeared. It was rather worrying at the start as you tend to question whether you’re making it worse rather than improving things!

| Sanding started with 600-grit |

Followed by 800-grit |

|

|

The grade of paper was then progressively made finer at each pass, finishing with 2000-grit. The aluminium started to gain an even sheen during the last few passes and then it was ready for polishing.

Fortunately I had a second bench grinder and so replaced the stones with two 6″ polishing wheels; one for use with a cutting paste and one for the final polishing paste. I’m sure it would have been a much more difficult task without it or trying to fit a polishing wheel to a power drill.

| Getting close : 1500-grit |

2000-grit produces an even sheen |

After polishing with cutting paste |

|

|

|

The polishing cutting paste soon obtains a smooth shiny finish. Once the majority of surface blemishes have been removed, the polishing paste is used to obtain the final finish. The key point is to polish evenly rather than over polishing by concentrating on a specific area. It’s surprising how much heat is generated during the polishing process so there were frequent breaks to allow the wheel (and motor) to cool.

The steering wheel boss was also given the same treatment.

I believe the aluminium spokes were originally protected by a clear lacquer. I used Pro-XL two pack clear lacquer which should provide a tough scratch resistant layer, with both the steering wheel and boss given three coats. The curing time is 24 hours after which it can be mechanically polished.

However, once the aerosol is activated, it only has a pot life of about 24 hours. So it’s not possible to address imperfections in between coats. It was a fine line between getting an uneven orange peel finish and over-spraying causing runs.

However, once the aerosol is activated, it only has a pot life of about 24 hours. So it’s not possible to address imperfections in between coats. It was a fine line between getting an uneven orange peel finish and over-spraying causing runs.

I managed to get a combination of the two! Plus a few high spots due to dust pick up and areas where the lacquer flowed through the holes in the spokes and pooled underneath.

The wheel and boss were then rubbed down with 2500-grit wet & dry paper to correct any imperfections, adding a little water to the surface before sanding. A sanding block is a good idea for the wheel to ensure a flat finish.

The lacquer takes on an opaque appearance once sanded so removing areas of orange peel was very easy. Once the glossy low spots had disappeared, producing a uniform opaque finish, it was ready for buffing up with some standard polish. In this case, Menzerna Fast Gloss FG400.

Finally, it was time to re-rim the wheel! A suitable epoxy that had been recommended to bond the rim was Pacer Z-poxy. Several types are available, having different curing times. I opted for the 30 minute variety (PT-39) to provide plenty of time to make any adjustments! Like many epoxies, the resin and hardener are mixed in equal quantities.

To be on the safe side, I chose to tackle it in two stages; first bonding the aluminium wheel into the grove in the lower half and then once cured bonding the top half. The only issue was to make sure the countersunk side of aluminium wheel was the right way round!! Numerous clamps were used when bonding the second half of the rim, alternating between clamping the two halves together and ensuring the edges of the two halves were perfectly aligned.

One of the reasons for choosing Z-poxy was that it can be sanded. However any excess squeezed out by the clamping was quickly removed with methylated spirits. If I were to do it again, I’d not use the clamps to keep the edges of the two halves aligned. Clamping in this way did not squeeze out all the excess epoxy, so there is a slightly more visible join in places. Nothing too disastrous but not perfect.

A better approach would have been to use all 8 clamps to squeeze the halves together a firmly as possible. Any slight alignment issues could then be addressed when the rim is sanded down before the final finishing.

I believe many of the steering wheel restoration companies then apply a hard polyester lacquer to the rim. Although I’ve decided not to go down that route for a number of reasons; it’s not readily available, difficult to apply and I think not as pleasant in the hand.

My preference is just to apply Colron finishing oil to keep the natural feel of the wood. The aluminium spokes were masked off and the wood sanded down with 240-grit and then 320-grit sandpaper. My preference is just to apply Colron finishing oil to keep the natural feel of the wood. The aluminium spokes were masked off and the wood sanded down with 240-grit and then 320-grit sandpaper.

The finishing oil was then wiped on with a lint-free cloth and allowed to dry for approximately 5-6 hours between coats. Once each coat had dried, the rim was rubbed down with ultra fine Steel Wool (0000) before applying the next coat.

|  Initially the oil produces a matt finish which progressively becomes glossier as additional coats are applied. In the end I had applied about 12 coats until I had the finish I wanted. Initially the oil produces a matt finish which progressively becomes glossier as additional coats are applied. In the end I had applied about 12 coats until I had the finish I wanted.

To keep the wheel in tip top condition, it should only be a matter of rubbing down with steel wool and reapplying additional coats. Far easier maintenance wise than varnishes or lacquers.

The downside of finishing oil is that it doesn’t offer the same protection against damage that a hard lacquer would provide. I’ll just have to be careful.

| After multiple coats of finishing oil …. the final finish |

|

|

|

The final problem was the central E-Type motif (or horn push for the earlier cars – the S2 horn being operated via the indicator stalk). The clear plastic had numerous fissures on the surface and some had propagated to reach the base, causing these areas to lose the gold colouring.

| Surface cracks on horn push |

Comparison: Repro (L) v Original (R) |

|

|

I’d hoped that it might be possible to repair it, in a similar manner to repairing cracks in windscreens. However my investigations so far have not found a suitable method to repair it. The general consensus on the E-Type forum was that it wouldn’t be possible to repair.

A reproduction motif was purchased as a fall back but I hadn’t noticed the differences between the originals and the repro ones until the moderator of the forum pointed them out; the colouring is more of yellowy silver than the deep gold of the original.

Why they can’t get simple things like this right I’ll never know. Chinese no doubt! So I’ll fit the repro one for now until an original comes up on eBay. Fingers crossed …..

Fortunately the vinyl covering of the dash fascia was in a reasonably good condition and just needed a good clean. Even though only a very mild detergent was used, the cleaning couldn’t bring back the lost sheen and depth of colour. After cleaning, it had an almost whitish appearance in the lower areas of the textured finish.

Apparently vinyl can ‘dry out’ and harden over time so I applied some trim restorer (Gtechniq T4) to see if this would help. The product is simply wiped on and left to dry. It worked a treat in restoring a deep black colour and satin finish. The photos below show the difference in appearance with and without the trim restorer (although the treated areas appear slightly glossier than in the flesh).

The rears of the facia were treated to a clean-up: Brasso for the copper plated central instrument panel and paint for the outer facia panels. The outer panels were showing signs of rust through the plating in places but it’s not possible to re-plate due to the vinyl coating.

The heater, demister and choke controls were also all looking rather shabby as areas of the wrinkle paint had been worn away. Rather than go down the route of powder coating these, like the cooling fan shroud, I decided to try to get a decent wrinkle finish using an aerosol can ….

…. well four in fact! For the first attempts, Halfords own brand of wrinkle paint was used. Utterly useless! The nozzle failed on the very first application, leaving paint spewing out around the nozzle until the entire can had discharged. I should have opted for the refund but foolishly decided to persevere instead. I’d got through almost the entire can (and my patience!) trying to get anything near to either an even or a wrinkled finish. Both? Forget it.

Common sense returned and I took great pleasure in hurling the remainder of the can into the bin. The next Hycote branded can came from an Auto Factors and wasn’t much better. In a final attempt, I purchased a can of VHT wrinkle paint as I’d found their products to be quite good when painting the alternator and back of the heat shield.

A mock up bracket for a boot light switch was used as a test piece. The instructions were followed to the letter: 3 coats of paint with exactly 5 minutes between applications. The paint goes on with a smooth glossy finish but soon wavy ripples appear. VHT recommend curing the paint by heating to 93 0C for an hour. Two test applications were made: the first left to dry naturally for several days before being cured while the second was left for five minutes before being placed in the oven.

| A gloss finish initially |

Dried in ambient temp |

Oven dried finish |

|

|

|

I preferred the more wrinkled finish produced by immediately curing the paint in the oven. It was easier to spray and cured one side of the levers and knobs at a time. The heater and demister levers simply pivot on the mounting bolt. However the movement of the choke lever is given an incremental feel by a leaf spring pressing a ball bearing, located within a hole in the lever, against a plate with evenly spaced ball bearing sized holes.

| Oven curing |

Heater & Demister levers |

Choke lever, less leaf spring |

|

|

|

A couple of practical but discreet enhancements require holes to be cut into the cardboard glove box. So, rather than butcher the original, a replacement glove box was fitted although like most reproduction parts it wasn’t a brilliant fit.

The top of the glove box is held in place against the facia by a retaining bracket while the bottom edge was originally secured with bifurcated rivets. The only suppliers of these types of rivets sold them by the 1000 and were based on the other side of the world. So standard 3.2mm pop rivets with washers were used instead.

There needs to be a gap between the facia panel and the bottom of the glove box in order to slot in the under-dash cardboard trim panel. Therefore suitably size spacers were needed over the rivet – 5mm thick M3 nylon washers were just about spot on.

| Securing bottom of glove box |

USB and Megajolt sockets |

Connections hidden from view |

|

|

|

As almost all modern gadgets are now powered/charged via the ubiquitous USB socket. I thought it sensible to tuck a double USB socket in the glove box to power phone chargers and Sat Nav while being out of sight. The sockets will be powered once the ignition is switched on.

The EDIS Megajolt unit for the electronic ignition can be programmed by connecting it to a PC via a serial port connection. To avoid needing to remove dash trim to reprogram, I’ve also put a 9-pin serial socket in the glove box. This is permanently wired to the Megajolt unit so any future programming of the electronic ignition system should be a doddle.

The outer heater and demister cables are clamped to a bracket mounted on the bulkhead. The only error I made was to connect up the interior heater valve cable before routing the inner cable through the valve’s trunion in the engine bay. It’s then impossible to fit the trunion onto the heater valve.

The positioning of the USB and serial sockets had to take into account the rear clearances as well as the routing of the demister tubing. With the dash fascia completed, next I’ll have to tackle the LED lighting for the various instrument gauges.

Update:

A while back I had been looking at adding either intermittent or even automatic wipers. However I’d shelved the plans as I hadn’t come across anything that could easily be reverted back to the original setup.

Once again a couple of the main protagonists on the E-Type forum had investigated suitable units and worked through how to incorporate it into each of the E-Type variants. So other owners wishing to do likewise have detailed fitting instructions and needn’t go through the pain of trial and error installing it. It even covered various mounting positions; either using a blanked off hole in the dash or more discreetly under the dash. Once again a couple of the main protagonists on the E-Type forum had investigated suitable units and worked through how to incorporate it into each of the E-Type variants. So other owners wishing to do likewise have detailed fitting instructions and needn’t go through the pain of trial and error installing it. It even covered various mounting positions; either using a blanked off hole in the dash or more discreetly under the dash.

I decided to mount the intermittent wiper module, manufactured by Hella, in the hole in the dash above the Handbrake/Brake Fluid warning light. I’m not sure what this hole was originally used for. I assume either something specific to the FHC or an optional extra. However it was just blanked off on my car.

The unit works by producing a power ‘pulse’ which mimics switching the wiper motor switch on and then off. The wipers start to operate but, as the power is removed almost immediately, the wipers will stop the next time they reach the parked position, ie after performing a single wiping cycle. The frequency of the intermittent wiping is simply varied by turning the unit’s potentiometer knob. I’m not sure about the style of the knob so it might be replaced with a plain black one at a later stage.

It was frustrating to have gone through the process of re-plating/re-chroming all the individual components and to have rebuilt the handbrake, only to find that the ratchet had been butchered to fit an incorrect cable. Rather dispirited, I decided to keep the rebuilt handbrake as is and reuse the offending cable.

I’d hoped that it would be possible to rig up an alternative method of mounting the handbrake switch. However I wasn’t able to come up with a solution that I was happy with. Plus I’d found a number of forum postings of issues setting up the handbrake mechanism even with the correct, unmolested parts.

| Old & New Clevises |

Correct cable is shorter |

|

|

The existing cable was either incorrect for the car or a poor reproduction part. Both of its clevises were far too long, resulting in an inner cable length that was over 1/2″ too long.

I’m fairly sure that a previous owner/garage had relocated the cable abutment on the ratchet about 1″ rearward as a bodge to compensate for the oversized clevis.

The knock-on effect is the distance between the outer cable abutment on the ratchet and that at the handbrake compensator mechanism on the IRS has been reduced by the same amount. Squeezing the outer cable into this shorter distance effectively reduces the overall inner cable length by 1″ – so a net shortening of approx. 1/2″. The knock-on effect is the distance between the outer cable abutment on the ratchet and that at the handbrake compensator mechanism on the IRS has been reduced by the same amount. Squeezing the outer cable into this shorter distance effectively reduces the overall inner cable length by 1″ – so a net shortening of approx. 1/2″.

The handbrake compensator offers some adjustment to cater for stretching of the cable over time. Even so, 1/2″ would almost certainly put it at the limit of its adjustability. I’d probably be on a losing wicket trying to get it to work correctly. It was better to bite the bullet now rather than later. So a correct cable was obtained from the Jaguar Enthusiast Club, who now offered them via their online shop.

RM & J Smith were able to supply new ratchets which came as a relief, so it wasn’t necessary to buy a complete new handbrake. The only obvious difference is the pivot bolt spacers are welded to the replacement ratchets.

The fitting of the new ratchet was a simple task but the completion of the handbrake was foiled yet again. The bore of the outer cable abutment was 1/32″ smaller than the 3/8″ cable diameter. It has a slot machined into its circumference and is designed to allow a slight expansion, so I didn’t think anything was amiss. The fitting of the new ratchet was a simple task but the completion of the handbrake was foiled yet again. The bore of the outer cable abutment was 1/32″ smaller than the 3/8″ cable diameter. It has a slot machined into its circumference and is designed to allow a slight expansion, so I didn’t think anything was amiss.

The bolt securing the switch bracket then clamps the abutment onto the outer cable.

The only way I could get the outer cable into the hole was by continually twisting and pushing it. It didn’t feel right the more I progressed. Considerable effort had been needed just to get the cable half way home. So I decided to remove it and have a re-think. It might be possible to re-drill the bore although I was concerned the slot might cause problems.

I needn’t have worried. As soon as the cable was twisted in the reverse direction, disaster struck …. one half of the abutment fitting snapped clean off. I needn’t have worried. As soon as the cable was twisted in the reverse direction, disaster struck …. one half of the abutment fitting snapped clean off.

Aaaaargh and much cursing of repro parts!! Another case of what I now refer to as the Restoration March …. 1 step forward, several back!!

Looking at the fracture, it appears that the whole ratchet is hardened during the manufacturing process, presumably to provide the necessary hardness in the ratchet teeth. The downside, as I found out, is it makes the part brittle and prone to stress fractures. Not ideal for clamping parts which need a degree of ductility, such as the cable abutment.

RM & J Smith have been an excellent source of difficult to find parts and, to their credit, were very good, offering to send out a replacement immediately free of charge. They had identified the problem with the size of the hole and returned the ratchets to their manufacturer to be corrected. I had received one that slipped through the net. The following day the replacement arrived and it fits perfectly.

Getting the warning light switch properly set up proved to be much trickier than I’d anticipated and quite frustrating. The switch is activated by a ‘S’ shaped spring striker. When the handbrake is fully released the protrusion at the base of the lever presses against the striker, which in turn depresses the switch.

The main problem was mounting everything far enough forward so there was sufficient pressure on the striker to operate the switch. The main problem was mounting everything far enough forward so there was sufficient pressure on the striker to operate the switch.

Both the switch and striker are mounted to the bracket by two locking half nuts. So there is very little fore and aft adjustment that can be made. Mounting the switch progressively nearer to the striker starts to pre-engage the switches’ plunger, making the switching more hairpin-like until ultimately it’s permanently on.

I finally got it set up and working on the bench although I still wasn’t 100% happy. The switch had to be angled slightly and the warning light would be on as soon as the lever was moved off the end tooth of the ratchet. The plan was to mount the pre-built handbrake and switch but much to my dismay, I’d completely missed that fact that the cable has to be fed forward into the cabin through a guide bracket in the transmission tunnel.

All the set up was then lost, as the handbrake switch needed to be removed to free the cable. In situ, it wasn’t possible to reproduce as good a set up as before because the floor pan was stopping the angling of the switch. I found the best fit to mount the ‘S’ shaped striker horizontally.

I’m tempted to add some packing washers between the striker and bracket to allow the switch to be moved forward slightly. I think I’m going to leave the fitting the central console until after its first MOT so I’ll still have access to the handbrake.

There’s been a dramatic drop off in progress with the restoration in the last month or so. Partly due to the horrible winter weather, resulting in an apathy to venture out into a cold, dark garage!

In the meantime, attention has turned to sorting out bits and pieces that could be worked on indoors, although it gives an excuse for the gratuitous inclusion of some photos of the main reason for the lack of headway … a diving trip in warmer climes!

| Progress is delayed due to a spot of diving …. with some immature 6m Whale Sharks |

|

|

|

Back to the plot …..

Several years ago I’d come across an owner’s restoration of a ’63 OTS where they had redesigned the looms to their own specification, incorporating relays for the headlight circuits. The addition of relays made good sense, as they remove the main current bearing wires from behind the dash area, but I wasn’t convinced about having bespoke wiring looms made.

Deviating too far from the original wiring looms would mean that, if I subsequently encountered electrical problems, I’d be on my own as it would be hard seeking accurate advice from fellow owners. There was also the fear of overlooking a critical wire when the looms were made up or getting the length of one of the wires slightly wrong. It would be an expensive mistake to fix!

So the idea of adding relays was shelved and a new set of standard looms purchased. Fortunately this proved to be the right course of action. At the time, I hadn’t spotted the wiring diagrams I was using weren’t correct for my car. They didn’t have the changes in circuitry covering the introduction of the ballast resistor into the ignition circuit.

Rather timely, as I was starting to look at the lighting and bonnet electrics, an excellent write up of a headlamp relay modification was covered on the E-Type forum. The installation is very discreet with the relays being mounted out of sight behind the LHS ‘sugar scoop’. The only visible sign of the modification is the main power feed, taken from the alternator B+ terminal.

The downside of tucking the modifications within the bonnet is that it will be much trickier to maintain if something fails. The headlight bowls and possibly the indicators would need to be removed to gain access.

I had some spare repro 6RA relays so all I needed to purchase were some suitable coloured & rated wires and two in-line fuses. I also decided to install Halogen headlights at the same time. I had some spare repro 6RA relays so all I needed to purchase were some suitable coloured & rated wires and two in-line fuses. I also decided to install Halogen headlights at the same time.

The circuit diagram shows the planned wiring modifications, with the additional components labelled in red.

There are two spare terminals in the 8-pin bonnet plug, which were originally for the bonnet mounted horns found in the earlier cars and, I believe, the provision for optional extra spot/driving lights.

One of these spare terminals was used for the single high load wire running from the alternator B+ terminal to the 10-way connector in the bonnet. (It’s much easier to take a supply from the B+ post rather than travelling all the way back to the battery.) One of these spare terminals was used for the single high load wire running from the alternator B+ terminal to the 10-way connector in the bonnet. (It’s much easier to take a supply from the B+ post rather than travelling all the way back to the battery.)

I managed to feed the wire into the PVC sleeving to the bonnet plug so the only visible sign of the installation in the engine bay is a single sheathed wire running from the alternator to the bottom left of the picture frame, which has been cable tied to the existing loom.

From the bonnet connector, this feed splits in two to provide the 12v supplies to the dipped and the main beam relays. The relays have a double spaded terminal for the switched output, so the wires to the left and right hand lamps were connected directly to the relay.

Wire and fuse ratings

The Halogen dual filament bulbs are rated as 55W/65W at 12v so the dipped and main beams for each bulb will draw around 5.5 amps and 6.5 amps respectively (assuming a charging battery voltage of 14.3V).

Normally only one set of the filaments are on at any one time. However the worst case is when the main beam is ‘flashed’ while the dipped beams are on. Even though this should only be for short periods of time, I thought it prudent to assume the maximum current required for both headlamps would be 24 amps (2 dipped @ 5.5A each and 2 main beam @ 6.5A each).

Therefore 44/0.30 cable, rated at 25 amps, has been used for the supply from the alternator rather than the 28/0.30 cable suggested in the forum write up. Inline fuses have been used for the connections to the two relays. Their wiring is rated at 30 amps which is more than enough, although they have both been fitted with 15 amp fuses as the expected loads are 11 amps dipped and 13 amps main beam.

Using two fuses should ensure that a blown fuse won’t result in the complete loss of lighting! Using two fuses should ensure that a blown fuse won’t result in the complete loss of lighting!

The original wiring for the dipped beam (Blue/Red) and main beam (Blue/White) will now just be used to switch the relays. The coil resistance for the 6RA relays was measured at approximately 83 ohms so the switching wires will now only need to carry around 0.17 amps. Therefore the dash mounted fuses 1 & 2 have also been replaced, by 0.25 amp fuses.

As the whole bonnet area had been coated in copious amounts of Waxoyl, I also fitted some PVC sheathing to the bonnet loom in an attempt to keep it clean. I just need to tidy up the cabling when the headlamps are fitted.

Unfortunately the heater box was beyond economical repair. The entire bottom section was paper thin and had rusted through in places. The side joints hadn’t fared much better and had rusted from within causing the joints to swell. Unfortunately the heater box was beyond economical repair. The entire bottom section was paper thin and had rusted through in places. The side joints hadn’t fared much better and had rusted from within causing the joints to swell.

Every time the heater housing was rotated to inspect it, showers of rust fell from every opening! The motor and fan cage were also missing.

The heater matrix within is surrounded by a thick felt material and I suspect that this had acted as a sponge. The absorbed water had sat against the base and sides causing them to corrode over a prolonged period of time.

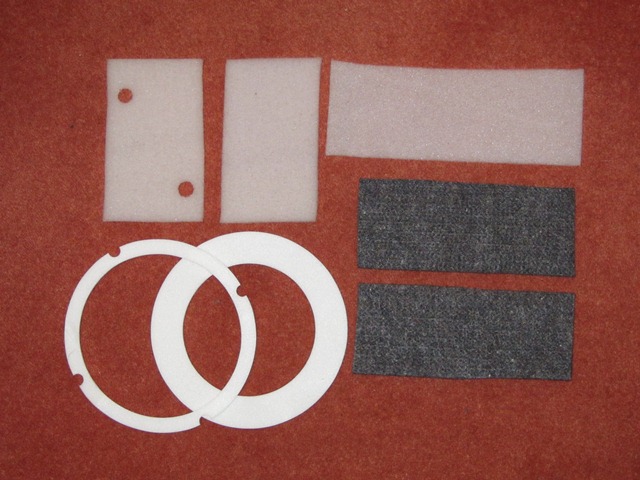

Fortunately new heater units are available (although not that cheaply), so a new one was ordered along with a heater matrix and a kit containing all the various padding materials. Fortunately new heater units are available (although not that cheaply), so a new one was ordered along with a heater matrix and a kit containing all the various padding materials.

Oddly the padding kit didn’t include the square rubber seal fitted between the heater body and the bulkhead.

If you were going to the effort of replacing all the internal padding, it’s likely you’d be working on the fan housing off the car and so would probably need to replace the bulkhead seal too!

On the positive side, the new heater has an improved design for the fan cage which hopefully might address the reported problems with the original, asthmatic unit. The blades on the original fan cage were flat and aligned radially which isn’t the most efficient in generating a throughput of air. The new cage has curved blades angled towards the direction of rotation.

The heater motor can be switched between two operating speeds and is achieved by introducing a resistor into the circuit to reduce the voltage across the motor. It’s riveted to the motor’s mounting flange and the loom wires soldered in place rather than using spade connectors. I’d stupidly expected a new unit would come with the resistor attached!

The padding around the heater matrix is a thick fibrous material and it was a really tight squeeze to fit it all in. At least the matrix won’t be able to move around!

I found it was necessary to glue the square foam seal to the heater box with contact adhesive, before fitting the heat to the bulkhead. Otherwise, with only one pair of hands, it tends to fall out of place when attempting the fiddly task of fitting the mounting bolts while supporting the heater unit.

| Heater Matrix & padding |

Bulkhead seal glued in place |

Heater unit installed |

|

|

|

Fortunately the rubber connectors and ducting behind the dash were all present and in good order. So they only needed cleaning in soapy water to remove the grime that have built up over the years. Fortunately the rubber connectors and ducting behind the dash were all present and in good order. So they only needed cleaning in soapy water to remove the grime that have built up over the years.

As with many other cars of the period, E-Types use Lucas 6RA relays to control the power supply to the various electrical ancillaries, specifically those that draw larger currents. The obvious benefit of using a relay, an electrically operated switch, is it allows a high current circuit to be controlled by an isolated, low current circuit.

This enables all the wiring handling the highest currents to be located within the engine bay and controlled by low current wiring routed from the dash area. Removing the high current wiring from the dash reduces the potential fire hazard.

So it’s odd why Jaguar didn’t use relays to control the main and dipped headlights. The addition of headlight relays is another popular modification which I’ll be making in due course. The mounting of the horns was relocated from within the bonnet to the picture frame during the production run of the S1 4.2. This has freed up a connection in the 8-pin bonnet plug which can now be used for the high current feed from the battery and the relays can be discreetly located behind the headlamp sugar scoop.

Four types of 6RA relays are used in the later S2 cars (those with the ballast resistor):

- Alternator Relay – 33209F (SRB121) : 20A 4 pin

- Starter Solenoid Relay – 33231E (SRB400) : double contact 5 pin

- Cooling Fan Relay – 33232E (SRB501) : 3 pin

- Horn Relay – 33252E (SRB111) : 20A 4 pin

Note: the SRB numbers are the modern replacement product codes

To the right are diagrams detailing the external terminals and internal wiring for the four 6RA relays used in the S2. To the right are diagrams detailing the external terminals and internal wiring for the four 6RA relays used in the S2.

The difference compared to the earlier cars is the starter solenoid relay has double contacts to enable it to provide power to the starter solenoid as well as bypassing the ballast resistor while the starter is in operation. All are simple electromagnetic type relays, which are ‘normally open’.

The various relays were all working fine but were showing the effects of decades of exposure to the elements and looked very scruffy against all the restored components.

The relay covers are only crimped in four places so it was possible to carefully undo them to enable the covers to be removed. These were dipped in a mild citric acid solution overnight to remove the remains of the zinc plating before being re-plated.

With the exception of the 3-pin cooling fan relay, the W1 and W2 terminals are used to energise a coil winding which has an iron core at its centre. With the exception of the 3-pin cooling fan relay, the W1 and W2 terminals are used to energise a coil winding which has an iron core at its centre.

In the energised state the coil produces a magnetic field which draws a sprung, iron armature towards the iron core. In doing so a contact at the end of the armature (C2 terminal) makes a connection with a fixed contact, the C1 terminal or the C1 & C4 terminals for the double contact relay.

The 3-pin relay lacks a W2 terminal because it is designed for applications where terminal C2 is always connected to 12 volts. Internally the C2 terminal is also connected to the coil winding and so acts as the W2 terminal as well, delivering 12 volts. The coil winding is therefore energised by grounding terminal W1, resulting in the switching of the relay. The 3-pin relay lacks a W2 terminal because it is designed for applications where terminal C2 is always connected to 12 volts. Internally the C2 terminal is also connected to the coil winding and so acts as the W2 terminal as well, delivering 12 volts. The coil winding is therefore energised by grounding terminal W1, resulting in the switching of the relay.

All that remained was to tidy up the electrical connections and re-crimp the covers back in place.

Ignition Switch

As I was sorting out electrical bits and pieces, attention turned to the Lucas ignition switch, which is marked 157SA 39415A. I’m not sure if this has been replaced at some stage but the terminals bore no correlation to the wiring diagrams and had intermittent connections when tested with a multi-meter.

The terminal connections on the wiring diagrams indicate:

- 1 – Brown : supply from Battery, under permanent current

- 2 – White : under tension only after ignition switch is on

- 3 – White/Yellow : via starter solenoid relay, delivers power to the starter motor

Therefore, when the key is in position II, terminals 1 and 2 should be connected and when the key is in position III, terminals 1, 2 and 3 should all be connected.

To achieve this with my 157SA switch, the White/Yellow wire can only be connected to terminal 1. The other wires using terminals 2 and 3, in any order. I decided to take the switch apart to see if it was possible to ‘correct’ the terminal connectivity and address the intermittent connection problems.

The switch can be split in half by gently prising the retaining tabs outwards. The tabs are made of pot metal so I wasn’t sure they would survive the operation. The switch can be split in half by gently prising the retaining tabs outwards. The tabs are made of pot metal so I wasn’t sure they would survive the operation.

Inside the copper contacts were heavily ‘gunked’, which was the most likely cause of the intermittent connections, so they were cleaned up with good old Brasso.

The key lock engages with a nylon disc within the switch, which therefore rotates as the key is turned. On the underside of the disc is a sprung ball bearing which locates in dimples to differentiate the key positions and a spring which returns the key position from III (starter motor engaged) to position II when the key is released.

There’s no ability to change the terminal connectivity so I’ll just have to adjust the terminal wiring accordingly.

One of the first modifications I’d decided to make was the change to an adjustable reaction plate for the torsion bars. In part the decision was due to the enormous trouble I’d had removing the torsion bars and reaction plate.

Also, even though the front suspension should only need to be set up once, if there was some settling of the suspension after the rebuild, subsequent fettling would be far easier. So I purchased an adjustable reaction plate from Rob Beere and followed Bob Skelly’s excellent installation guide.

– PDF Version – PDF Version

I’d planned to install the front suspension and torsion bars on two previous occasions. However, both times, progress had been thwarted due to some other fitting ‘difficulties’ that had been encountered. The first when installing the IRS and subsequently the engine. I’d planned to install the front suspension and torsion bars on two previous occasions. However, both times, progress had been thwarted due to some other fitting ‘difficulties’ that had been encountered. The first when installing the IRS and subsequently the engine.

So it shouldn’t have come as a surprise that fitting the reaction plate would be equally challenging! The first problem was the adjustable reaction plate was approximately 3-4mm wider than the original. The tubes for the bolts securing the plate to the underfloor channels protruded much further beyond the outer edges.

Rob Beere suggested using a pry bar and the need for a tight fit, which may well need hammering to ‘persuade’ it into position. If this didn’t work, the ends of the tubes could be ground down slightly to fit. No matter what I tried I couldn’t get it to fit and so had to resort to the latter.

Even so, it still required hitting home with the nylon hammer. The various attempts to get the reaction plate to fit resulted in some damage to the paint work, which will need to be repaired. Even so, it still required hitting home with the nylon hammer. The various attempts to get the reaction plate to fit resulted in some damage to the paint work, which will need to be repaired.

Fortunately there are a number of other adjacent areas that still need to be touched up, where the chassis was attached to the support frame during painting. So these can all be tackled at the same time before the exhaust is fitted.

It was surprising to see that the new clutch slave cylinder had started to show some surface rust, even in the short time since the transmission was installed. I’ll have to treat it with some Dinitrol hard wax asap.

Bob’s instructions suggested tightening the large Allen key bolts once the upper bolts had been inserted. However I had slight alignment issues with all the mounting bolts and the torsion bar ‘ear’ brackets. Once the Allen and upper bolts were tightened, it was impossible to fit the remaining bolts and brackets.

I found it was necessary to have everything initially finger tight, which enabled a screwdriver to be inserted in bolt holes to pry the other mounting holes in the frame into alignment with those in the reaction plate. I found it was necessary to have everything initially finger tight, which enabled a screwdriver to be inserted in bolt holes to pry the other mounting holes in the frame into alignment with those in the reaction plate.

The fitting order that worked for me was the large Allen bolts followed by the ‘ear’ brackets, the upper bolts and finally the lower pre-cut bolts.

Only once all these were in place could everything, except the bolt through the ‘ear’, be fully tightened. It is worth reiterating that:

i) the Allen bolts need to be tightened before the adjusting cam is fitted, as the nut securing the cam obstructs access to the head of the Allen bolt

ii) the ear brackets needs to be at the top of their permitted travel before tightening the lower pre-cut bolts.

I also followed the advice of labelling the cam steps and then painting the outer face with some clear lacquer. However I didn’t bother highlighting the edges of the steps as I thought this was a bit of overkill. I also followed the advice of labelling the cam steps and then painting the outer face with some clear lacquer. However I didn’t bother highlighting the edges of the steps as I thought this was a bit of overkill.

With hindsight, I think not adding the highlights was a slight mistake. It would have provided a better visual guide to ensure the step of the cam is parallel with the edge of the torsion bar ‘ear’ bracket.

It’s not a major problem, provided there’s sufficient light when setting the cams. If I were to do it again, I’d use two bright, contrasting colours to paint alternate step edges.

I’d not been looking forward to fitting the torsion bars. I hadn’t been able to dismantle them in the conventional manner, described in the various service manuals. There wasn’t even a slight hint of movement in the torsion bars despite some very hefty blows wielding a club hammer. In the end, as an act of self-preservation, I conceded defeat and removed each side of the suspension as single units.

Time for some (dubious) Maths – the torsion bar setting link

The shock aborber is replaced by a fixed length link to provide a datum point when setting the torsion bars. This should then give the correct ride height, although the adjustable reaction plate would then come into its own if it needed subsequent tweaking. The setting link for the early cars was 17 13/16″, however this had increased to 17 31/32″ for the S2 cars.

I’d obtained some replacement torsion bars at Stoneleigh but hadn’t realised at the time that almost all new torsion bars are ‘uprated’. The standard bars are 0.77″ in diameter while the replacements were 0.85″. As a result, the bars will be stiffer, so using the recommended setting link length would result in the ride height being too high …. but by how much?

After some research I found that Classic Jaguar in America had produced a chart with recommended setting link lengths for various torsion bar diameters. After some research I found that Classic Jaguar in America had produced a chart with recommended setting link lengths for various torsion bar diameters.

Unfortunately they don’t have a figure for 0.85″ bars so I thought I’d plot their recommendations in order to determine the link length required. The graph wasn’t what I was expecting, with a linear relationship between the setting link length and the torsion bar diameter.

Hmmmm! Perhaps I’m missing something as I thought the torsional stiffness or angular deflection of a solid bar was inversely proportional to the diameter to the power of 4. Still, without anything better to work from, using a linear calculation the setting link length needed was 43.1cm.

Fitting of the torsion bars

The calculated length of the setting link should give me roughly the correct ride height (fingers crossed etc). So I chose to set the reaction plate cam to the mid-setting ‘4’ and will be able to raise or lower the ride height if it’s not exactly right. With the setting link in place and the ‘ear’ bracket locked at setting ‘4’, the rotational positions of the front and rear splines in the suspension are fixed. The calculated length of the setting link should give me roughly the correct ride height (fingers crossed etc). So I chose to set the reaction plate cam to the mid-setting ‘4’ and will be able to raise or lower the ride height if it’s not exactly right. With the setting link in place and the ‘ear’ bracket locked at setting ‘4’, the rotational positions of the front and rear splines in the suspension are fixed.

The torsion bar has a different number of splines at each end – 25 at the rear and 24 at the front. This provides a high resolution vernier adjustment, allowing the torsion bars to be set very accurately and therefore the ride height. The fitting of the torsion bar is now a matter of trial and error, rotating the bar by one rear spline at a time until the front splines are perfectly aligned with those in the wishbone.

A rotation of one rear spline is equal to 14.4 degrees while it needs 15 degrees of rotation to move on by one front spline. Another way of looking at it is when the bar is turned by one rear spline, the relative position of the front splines is altered by 0.6 degrees, in the opposite direction to the direction of rotation. The front splines will align perfectly for one of the 25 possible orientations!!

I had passed both splined ends of the torsion bars through their corresponding mating pieces a dozen or so times until I was satisifed it would only need three or four solid blows to hammer them home. I had passed both splined ends of the torsion bars through their corresponding mating pieces a dozen or so times until I was satisifed it would only need three or four solid blows to hammer them home.

The torsion bar need to be passed rearward through the rear ‘ear’ mounting and then forward again until the front meets the splined hole in the lower wishbone. However the splines were still too tight a fit. It was necessary to carefully file the spline faces on the torsion bar until it only took one firm tap to fully engage the splines.

This enabled the torsion bars to be pushed forward by hand until the front was 1mm or so from the rear face of the wishbone. A tap with the hammer would then bring the bar up to the wishbone, at which point it was possible to determine if the splines were correctly aligned. I used a 12″ pointed concrete chisel for a drift, so the point could sit in the indentation at either end of the bars.

The mistakes I made were:

- Smothering Copperslip over the front splines on both the bar and within the wishbone

- Blindly accepting the view that it’s a matter of trial and error to find the best fit

The Copperslip did a splendid job of masking whether the splines were properly aligned and so it was all wiped off. The best time to apply it was once the correct orientation had been determined and the front splines had just engaged.

I followed the advice of adopting a methodical approach of rotating one spline at a time until an exact fit was achieved. After completing one full rotation I wasn’t convinced I was any the wiser. The correct orientation had probably been missed under the cover of Cooperslip!

It was only at this point did I sit down and work out the Maths of the relative 0.6 degree movement of the front splines for a rotation of one rear spline. A couple of minutes of thought up front would have saved several hours of grief and frustration with a club hammer! Armed with that knowledge, it was then quite easy to quickly home in on a small area of splines spanning the best fit.

As an example:

| Front spline need clockwise rotation |

Result of rotating anti-clockwise by one rear spline |

Eventually an exact alignment is reached |

|

|

|

|

In the left photo, gaps can clearly be seen between the splines. The front splines need to be rotated clockwise to close these gaps. The middle photo was taken after the torsion bar had be rotated anti-clockwise by one spline. The gaps have clearly been reduced.

Eventually an exact or best match is achieved. Although I found when viewed from the lower inboard (7-8 0’clock) the front spline alignment would look spot on. However when viewed from the top outboard position (1-2 O’clock), gaps would be visible.

I think this is because the angle between torsion bar and the wishbone isn’t exactly at 90 degrees. So the lower inbound splines start engaging before the top outbound splines. Hence why gaps are still visible from one view and not the other!

Finally the torsion bars were both in and I’ve now less fear of tackling them again in future.

|

The intention had always been to paint the inside surfaces to provide better protection from the elements. So I decided to keep the new, rusty rear bumpers.